About this Site |

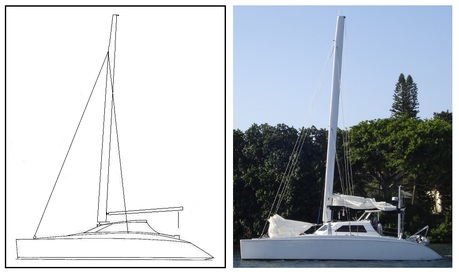

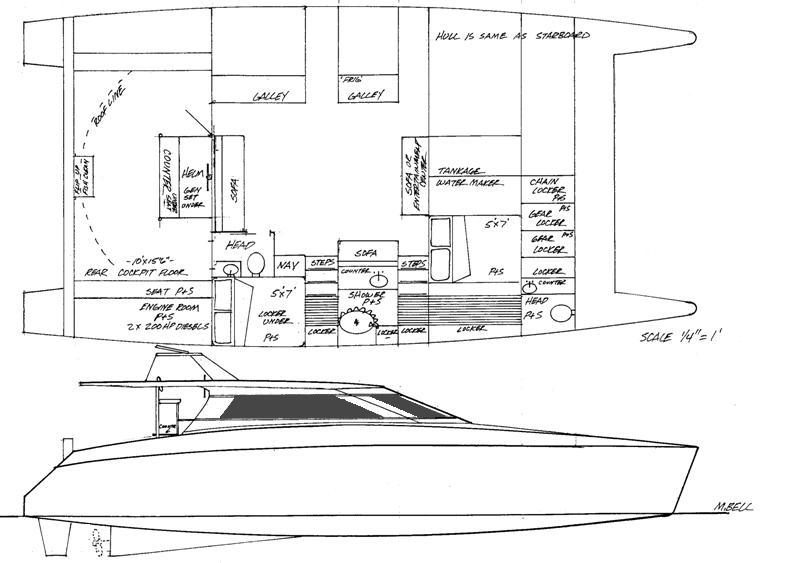

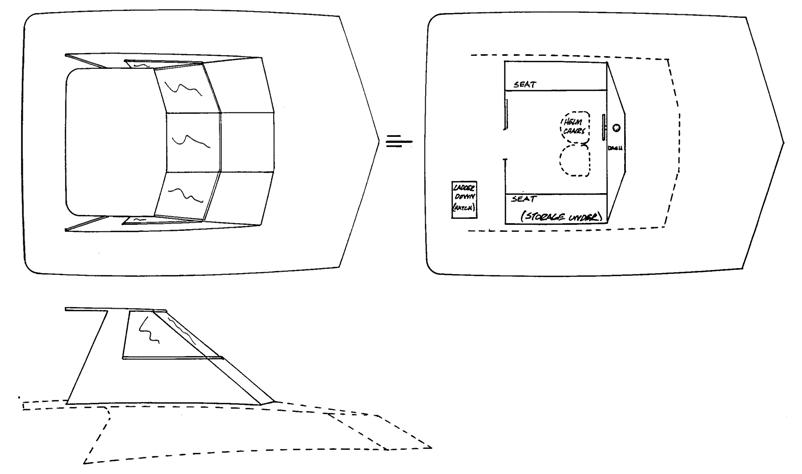

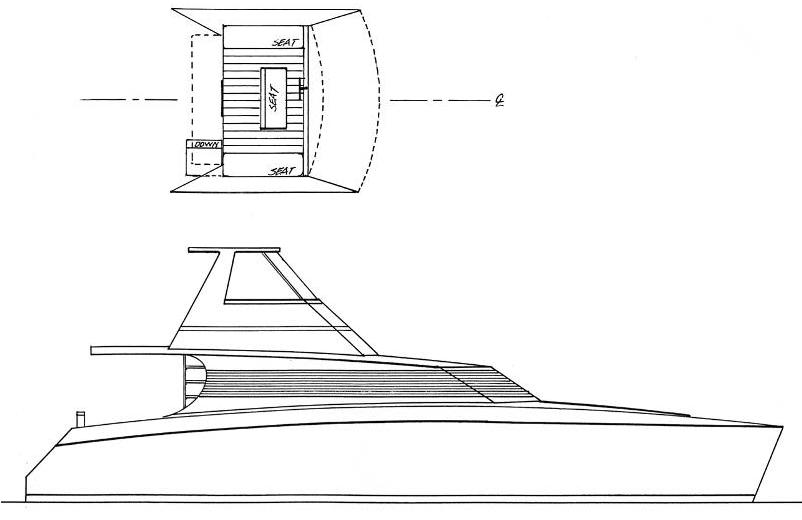

This website is a great resource for reviewing examples of what we can design and build; however, it is important to remember that you are not limited to what you find on the site. With all of our boats, we start off with a general concept for the catamaran, then work closely with the client to design exactly what they want. We are a catamaran design and construction company that caters to the client that wants something unique and custom.

|

A Letter from the Builder, Michael Bell |

Before I started building boats I was involved in the epoxy resin business in both marine and aerospace areas and I still maintain close ties with the major manufactures of epoxies for the latest developments. One of my clients in the 1970s was the world renowned CSK Catamarans, Rudy Choy, in Newport Beach, California.

We were one of the first builders in the world to use vacuum bagged epoxy laminates. All of our vessels have utilized a PVC foam core in hulls, decks and crossbeam structure. The use of a thick, but lightweight, core of PVC foam creates a very strong, stiff and very light craft. Two layers of fiberglass in epoxy resin is not very stiff, however, add a light weight PVC foam core between each layer and the strength and stiffness goes up dramatically. This core also gives flotation, insulation, is fireproof and is very durable. These cores never absorb water and cannot rot like wood cores. The use of epoxy resins also means very long life and never water blister like cheaper polyester resins. We only build in epoxy.

In fact, we have built several large catamarans that are totally demountable for shipping. We have also built composite wing masts for several of our boats and as replacement masts for other clients. Visit Lake Geneva in Switzerland and chances are you will see some sailing. We have been contracted to produce parts for not only catamarans, but also undersea, aerospace and medical projects.

Offshore Catamarans offers options customized to what you need, from plans, epoxy, materials, or boats built to any stage of completion. We also offer consultation services, along with arranging inspections and surveys of existing vessels. We invite you to study the photographs and our design plans on this web site. We can do everything from a stock design to a new custom design. We can make your dream a reality. A reality you can cruise the world on. Thank you, Michael Bell President Offshore Catamarans By BELL COMPOSITES, INC |

A Building History:

|

|